Choosing an appropriate enclosure.

In the past, the electrical enclosure was basically made of iron and applying the paint.But later, with the limitation of use and the requirement of environmental change, the concept changed.

Starting with the enclosure itself,Different applications and environments require different materials to match.In extreme environment, the junction box made of ABS or PC material is more suitable, such as cruise ship, electric power, chemical industry, petroleum exploitation, oil refining, military industry and so on.These extreme environments determine that the material needs to be corrosion-resistant, waterproof, dust-proof and pressure resistant.And protect the components inside and use them more safely.

The second feature is a new way of sealing.Different from the traditional sealing method, the ABS junction box is sealed with silica gel material. This material can completely separate the box from the outside, which has better antibacterial and waterproof effects. It can also be cut according to the size of the box, which is easy to replace, making it the best installation choice in different scenarios.

The third feature is the bolt material. The bolt of plastic box is made of ABS material, which makes the bolt not be corroded in harsh environment. It has better corrosion resistance, compression resistance and easier installation than metal bolt.

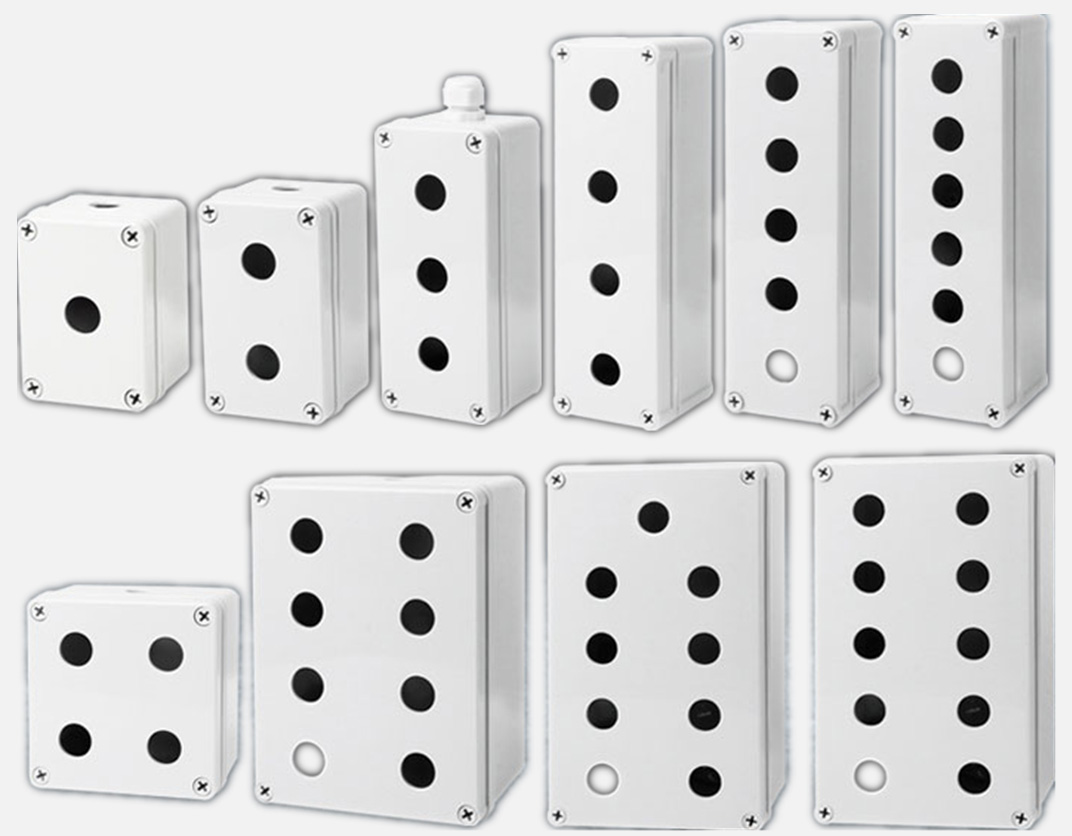

As a manufacturer of plastic enclosure,our production process strictly follows the IP grade.From raw materials, production line, product development, design, quality control,we check the whole process.We have a variety of sizes and shapes to meet the needs of different customers.To order your plastic enclousre, please visit www.wzmdbox.com or email Alex.c@wzmdbox.com.

Previous Could the plastic enclosure be used in different scenarios?

Next None